Contact Information

Telephone: +86 317 8308862

Skype:james521520

E-mail:admin@rollformingmills.com

Mobile phone: +86 187 3373 6699

Address: China Hebei Cangzhou Botou City 104 National Road East

YX6-32-1111 roof sheet forming machine customize

The products are widely used in industrial and civil buildings, such as factories, warehouses, stadiums, exhibition halls and other houses and walls. The company has a high starting point and an early start in the products of pressed tile molding and high-altitude pressed tile molding operation platform. So far, the products have been exported to more than 50 countries and regions such as the Philippines, Malaysia, South Africa, Zimbabwe, Russia, Argentina, the United States, and the United Kingdom, and with customers to establish a long-term cooperative development relationship. The roof sheet forming machine is an essential piece of equipment in the construction industry. It plays a crucial role in creating high-quality roof sheets with precision and efficiency.

Key words:

- Product Description

-

The roof sheet forming machine is an essential piece of equipment in the construction industry. It plays a crucial role in creating high-quality roof sheets with precision and efficiency.

This remarkable machine is designed to transform raw materials into durable and aesthetically pleasing roof sheets. With its advanced technology and capabilities, the roof sheet forming machine can produce a wide variety of roof sheet designs and shapes. It ensures that the final products meet the highest standards of quality.

Throughout the manufacturing process, the roof sheet forming machine operates with reliability and stability. Its precise engineering allows for seamless forming of the sheets, minimizing errors and maximizing productivity. It is capable of handling large volumes of production, making it ideal for both small-scale and large-scale construction projects.

Moreover, the roof sheet forming machine is highly customizable. It can be adjusted and configured to meet the specific requirements of different roofing applications. Whether it's for residential, commercial, or industrial buildings, this machine can adapt and provide the perfect roof sheets.

In addition to its functionality, the roof sheet forming machine also offers cost-effectiveness. By streamlining the production process and reducing waste, it helps businesses save on materials and labor costs. It is a valuable investment that brings long-term benefits to construction companies.

In conclusion, the roof sheet forming machine is an indispensable tool in the roofing sector. It continuously proves its worth by delivering high-quality roof sheets and enabling efficient construction processes. Five times or more, this machine showcases its importance and contribution to the building industry.

Product advantages

1. Long product life

We have reliable high-quality supporting suppliers, including Siemens, Mitsubishi, Delta, Panasonic, etc., as well as complete production processes, including post-painting assembly, strengthened frame structure, more reasonable roll-forming design, electromechanical hydraulic optimization and upgrading, etc.

2. High precision

Through AutoCAD, SolidWorks, UG, CATIA, PROE, our design team provides excellent roll forming solutions. As a manufacturer, we will guarantee the quality and high precision of all roller shafts, multiple machining of CNC lathes, key processes, polishing, and hard chrome plating.

3. Superior efficiency

The servo motor can not only provide powerful kinetic energy output for the mechanical drive, but also carry out precise intelligent control, which greatly improves the production efficiency of the roll forming machine.

4. High quality after-sales service

We provide a lifetime warranty for our products, and we can provide on-site installation and foreign debugging according to customer's requirements. A cooperation, lifelong friends!

Support customization

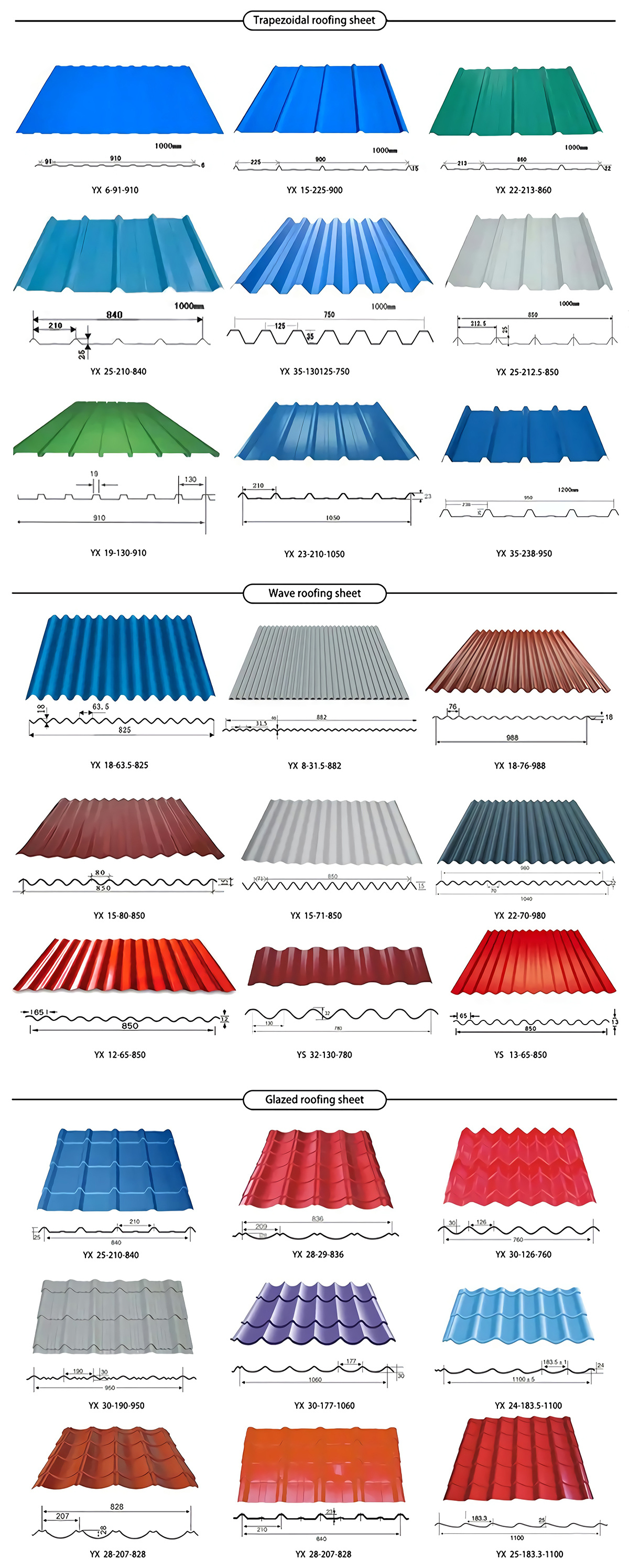

The machine is customized according to your drawings. Hot sale drawing brief for your reference.

About Us

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd. was established in 2008, The company focuses on theR&D and manufacturing of various types of roll forming machine, cold forming machine, and high-atitude tile makingdevices. The main products include color steel roll forming machines, alazed tile forming machines, C/z steel machines forPEB, floor deck production lines, high-altitude lifts, and high-atitude anti-suspended ceiling platforms. Products are widely used in industrial and civil buildings, such as factories, warehouses, stadiums, exhibition halls and otherhouses and walls. So far, the products have been distributed all over the country and exported to overseas markets. Exported to more than 50 countries and reaions including the Philiopines, Malavsia, South Africa, Zimbabwe, Russia, Araentina, the United States, and the United Kingdom, and has established long-term cooperative and developmentrelationships with customers.

Enterprise Honor and Qualification

Exhibition Information

FAQ

Q1 What are the key points in choosing the right machine?

A1: overall structure, roller shaft, roller material, motor and pump, control system. As a new buyer, please know that the price is not a definite price. Good quality is for long-term business cooperation.

Q2 Can you provide OEM service of roll forming machine?

A2: Yes, most cold roll forming machines need to be customized according to detailed requirements, because of the raw materials, size, production use, machine speed, then the machine specifications will be different.

Q3 What is your standard trade term?

A3: We can provide technical quotation such as FOB,CFR,CIF, door to door, etc. Please inform the detailed port name of competitive shipping.

Q4 How about quality control?

A4: Our company adopts 6s system to control each part, and passes the ISO9001:2000,CE,TUV/BV certificate.

Q5 after sales service?

A5: We provide 18 months free warranty and free technical support in the whole life cycle of any machine. During the warranty period, if the parts are still damaged, we can send new parts for free.

Q6 How can I visit your company if I am in Beijing, Shanghai or Guangzhou?

A6:

1) Beining South Station to Cangzhou West Station (1 hour by express train).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin, then Tianjin to Cangzhou West

Get Quote